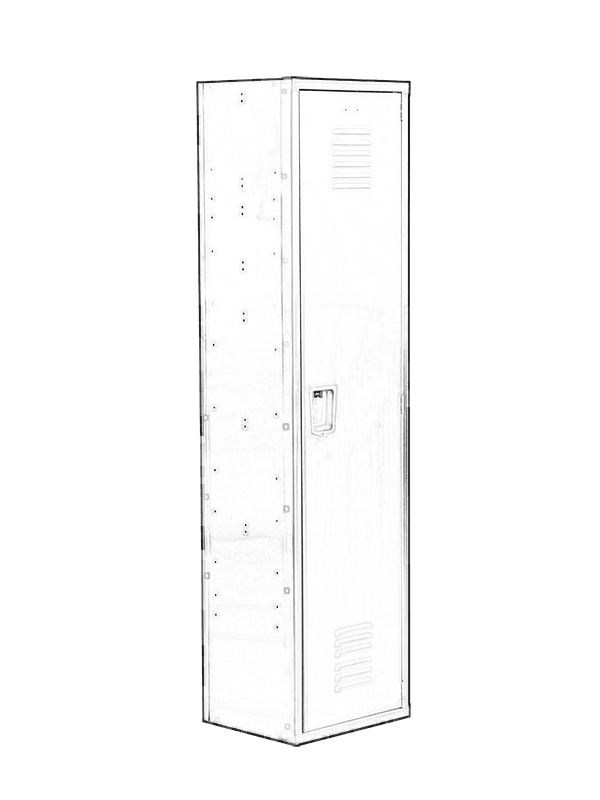

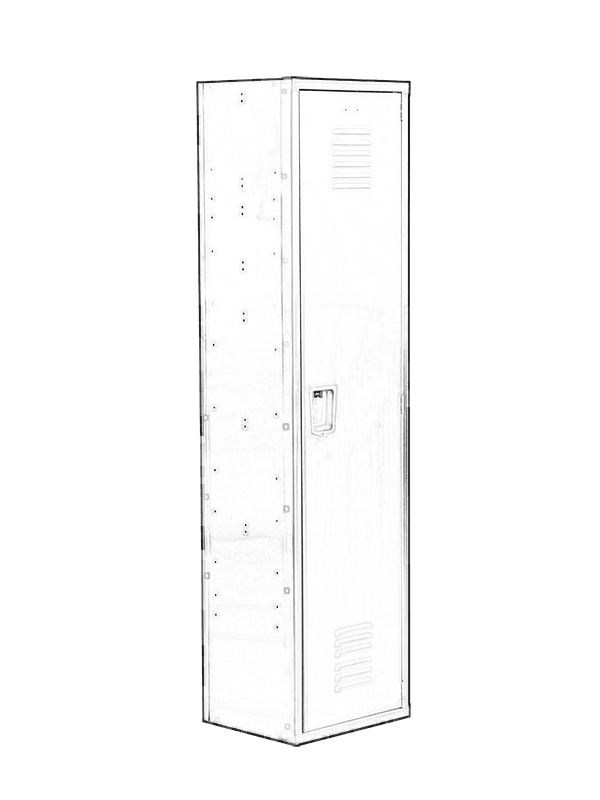

Selecting stainless steel locker for outdoor or high-humidity environments requires careful consideration of various factors to ensure durability, longevity, and functionality. Here are the key considerations:

Stainless Steel Grade: Choose the appropriate grade of stainless steel for the environment. While stainless steel is generally corrosion-resistant, some grades are better suited to outdoor or high-humidity conditions than others. Grade 316 stainless steel, often referred to as marine-grade stainless steel, is highly resistant to corrosion and is an excellent choice for such environments.

Sealing and Gasketing: Ensure that the locker design includes effective sealing mechanisms and gasketing to prevent moisture, dust, and other contaminants from entering the lockers. This is crucial to protect the contents from humidity and environmental factors.

Ventilation: Proper ventilation is essential in high-humidity environments to prevent the buildup of moisture inside the lockers, which can lead to mold, mildew, and rust. Look for lockers with well-designed ventilation systems or perforated doors that allow for adequate airflow.

Coatings and Finishes: Consider lockers with special coatings or finishes designed for outdoor use. These coatings can provide an additional layer of protection against UV radiation, saltwater exposure, and other environmental elements.

Locking Mechanisms: Select locking mechanisms that are corrosion-resistant and can withstand outdoor conditions. Stainless steel locks or electronic keypad locks designed for outdoor use are good options. These locks should also have seals or covers to protect them from moisture.

Hardware and Fasteners: Ensure that all hardware and fasteners used in the locker construction are made of corrosion-resistant materials, such as stainless steel or non-corrosive alloys.

Location and Installation: Properly assess the installation location to ensure that the lockers are placed in areas with adequate drainage and protection from direct exposure to the elements, such as heavy rain or direct sunlight. Elevating lockers slightly above ground level can help prevent water infiltration.

Maintenance Accessibility: Consider how easily maintenance can be performed on the lockers. Lockers should be designed to allow for routine inspections and maintenance to address any issues promptly.

Security: Ensure that the lockers offer appropriate security features, especially if they are located in public outdoor spaces. Choose locking mechanisms that are tamper-resistant and secure.

Customization: Depending on the specific requirements of the outdoor or high-humidity environment, you may need to customize the lockers to fit the available space, ventilation needs, and security requirements.

Warranty and Durability: Choose lockers from reputable manufacturers that offer warranties specifically covering outdoor or high-humidity use. This can provide peace of mind and assurance of product quality.

Budget: While durability and quality are crucial, consider your budget constraints. Stainless steel lockers designed for outdoor use may be more expensive than standard indoor lockers, but they offer long-term value in terms of durability and longevity.

By carefully considering these factors and selecting lockers designed for outdoor or high-humidity environments, you can ensure that your investment in stainless steel lockers will provide lasting functionality and protection for users' belongings in challenging conditions.

English

English 中文简体

中文简体