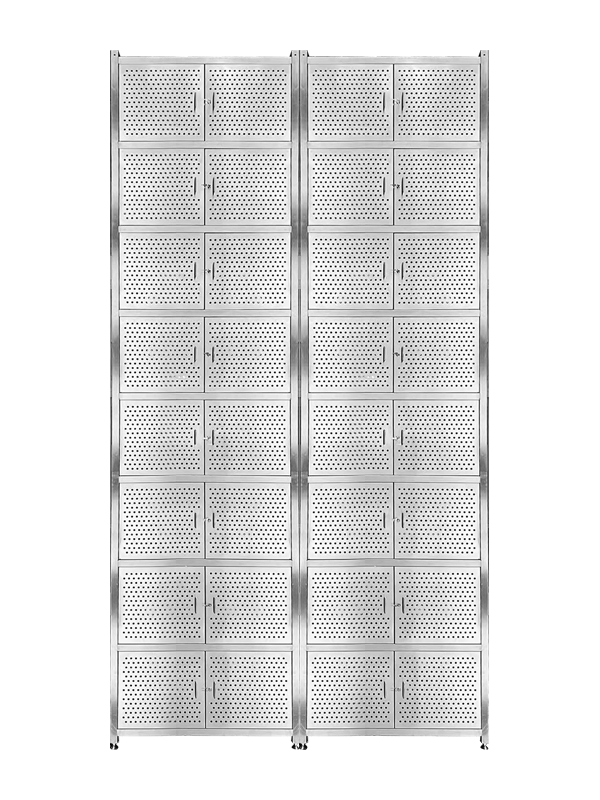

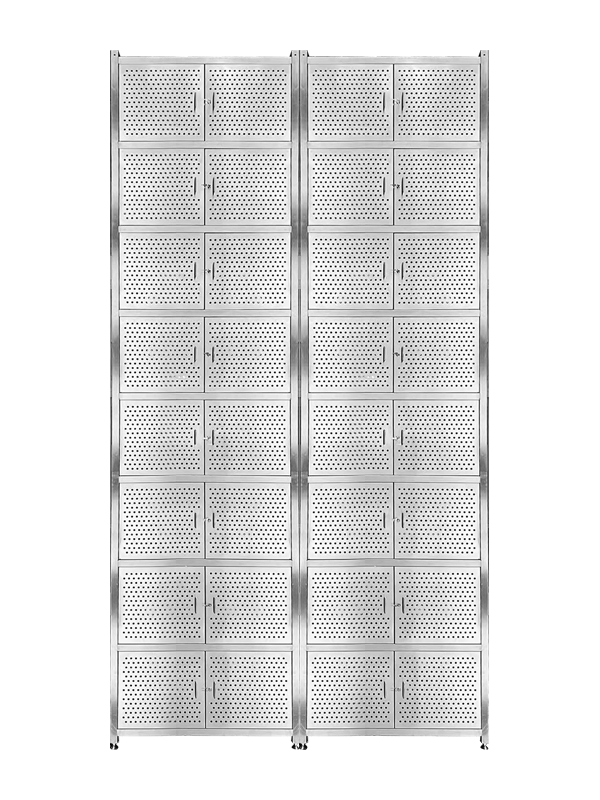

Loose fasteners on stainless steel locker can have several negative impacts on their performance and functionality. It's essential to address loose fasteners promptly to avoid these issues:

Security Risk: Loose fasteners compromise the security of the lockers. Hinges, locks, and other fasteners that are not properly secured can be tampered with or pried open more easily, potentially allowing unauthorized access to the locker's contents.

Malfunctioning Components: Loose fasteners can cause components like hinges, latches, and locking mechanisms to malfunction. This can make it difficult or impossible to open and close the locker properly, leading to user frustration and inconvenience.

Locker Misalignment: Loose fasteners can result in the misalignment of locker doors and frames. Misaligned doors may not close properly or may not align with the locking mechanism, making it difficult to secure the locker.

Increased Wear and Tear: Loose fasteners can cause increased wear and tear on the locker's components. Excessive movement and friction from loose hinges or latches can lead to premature wear, potentially requiring costly repairs or replacements.

Safety Hazards: Loose fasteners can pose safety hazards. If a locker door becomes unhinged due to loose fasteners, it can fall and cause injury to users or damage to their belongings.

Locker Appearance: Loose fasteners can affect the overall appearance of the lockers. Locker doors that are misaligned or have loose hardware may look unsightly and detract from the locker's aesthetic appeal.

Maintenance Issues: Lockers with loose fasteners require more frequent maintenance and attention. Neglecting loose fasteners can result in a higher cost of maintenance and repair over time.

Noise: Loose fasteners can create annoying noises when users open and close locker doors. This can disrupt the peace and quiet in locker rooms or other settings where lockers are used.

To prevent these issues, it's crucial to conduct regular inspections of stainless steel lockers and address any loose fasteners promptly. Tightening loose screws, nuts, bolts, and other fasteners using the appropriate tools and torque specifications recommended by the locker manufacturer can help maintain the security, functionality, and appearance of the lockers. Implementing a proactive maintenance schedule can further extend the lifespan of the lockers and reduce the risk of these negative impacts.

English

English 中文简体

中文简体