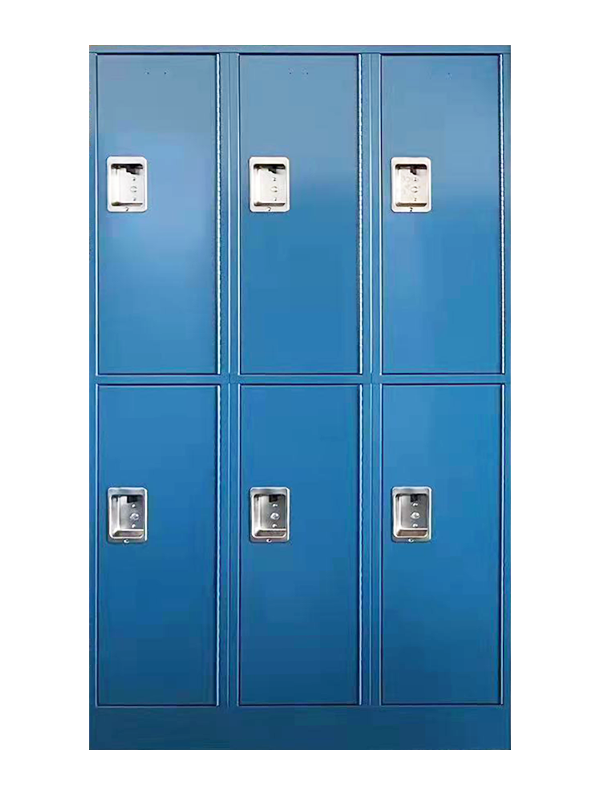

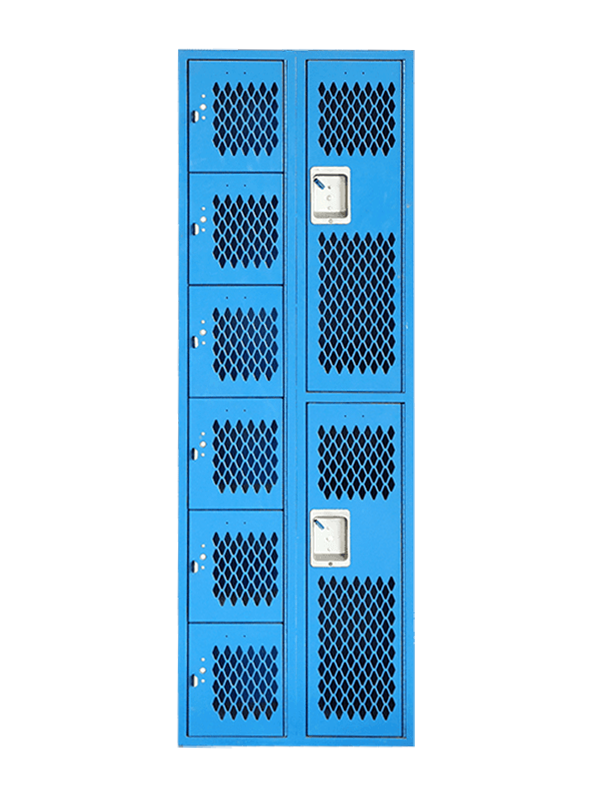

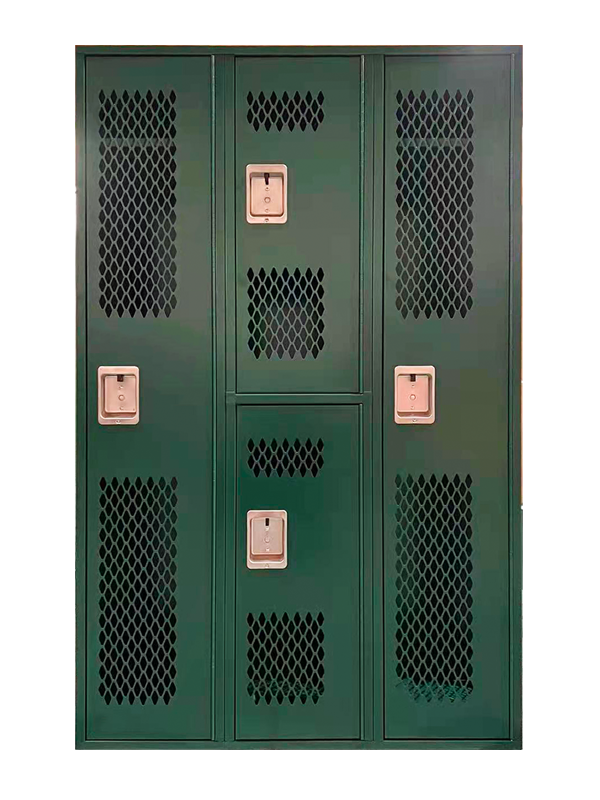

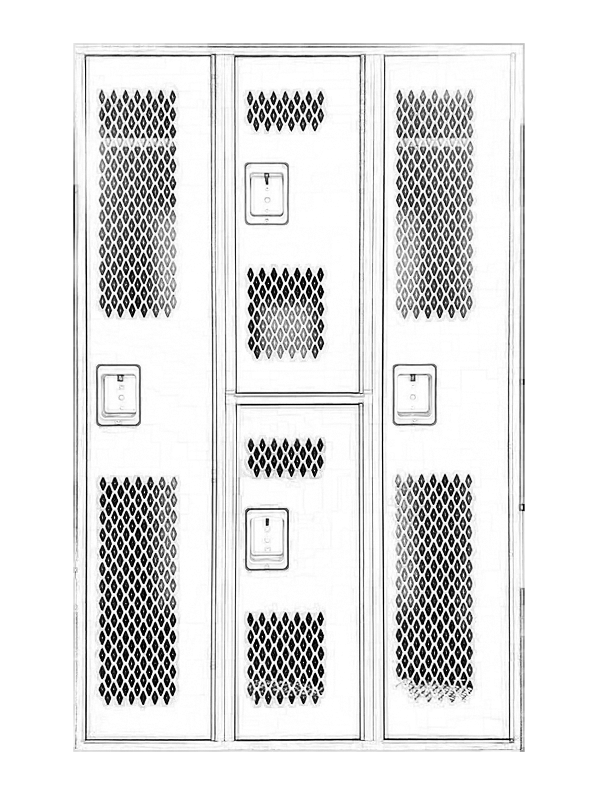

Welded lockers are storage lockers that are constructed using welded steel or other metals. The locker components, such as the frame, doors, and sides, are welded together to create a solid, durable, and secure storage unit.

Welded lockers offer several advantages, including:

Strength and durability:

Welded lockers are extremely strong and durable, making them ideal for heavy-duty use in environments such as schools, gyms, and industrial facilities.

Security: Welded lockers provide enhanced security, as the welded construction makes them difficult to break into or tamper with.

Low maintenance: Welded lockers require little maintenance, as they are built to withstand heavy use and resist damage from impacts, abrasions, and corrosion.

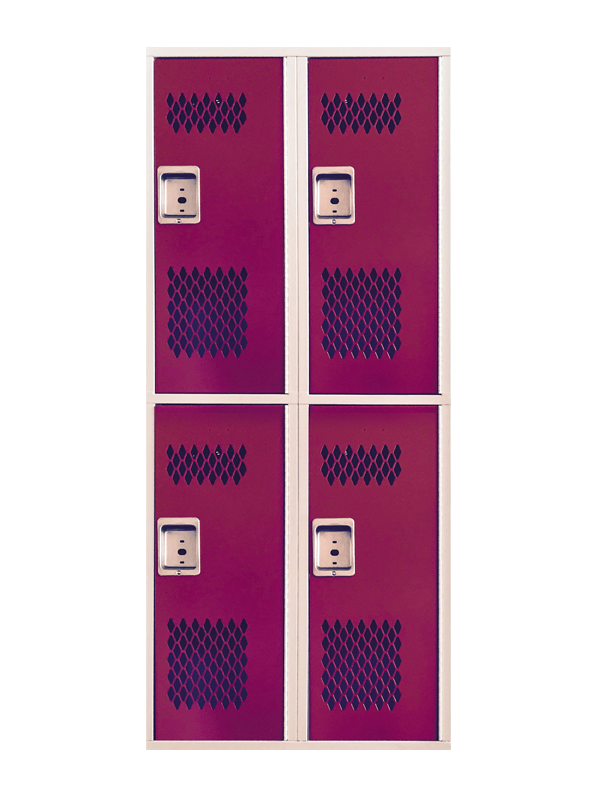

Customization: Welded lockers can be customized to meet specific size and configuration requirements, and can be finished in a variety of colors and textures to match the aesthetic of the surrounding environment.

Hygiene: Welded lockers are easy to clean and sanitize, making them ideal for use in environments where hygiene is a concern, such as schools and hospitals.

Overall, welded lockers offer a durable, secure, and customizable storage solution that is ideal for a wide range of settings and applications.

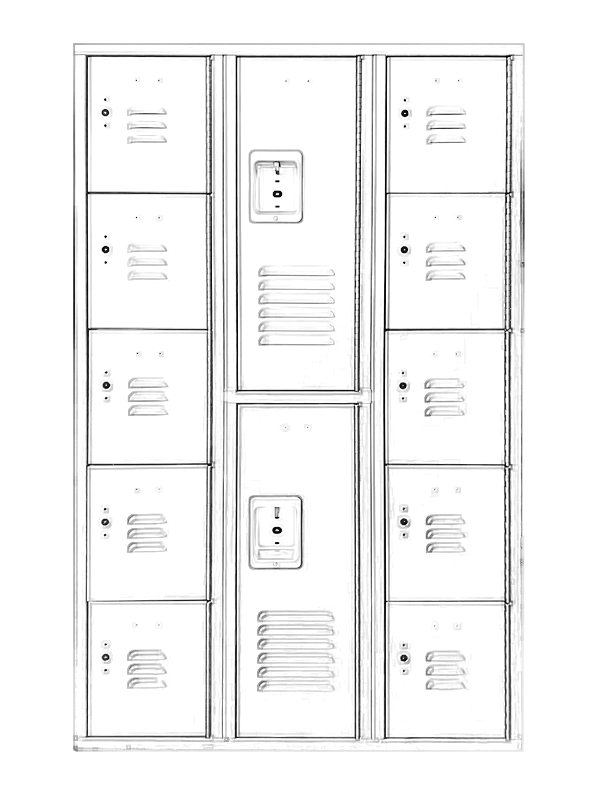

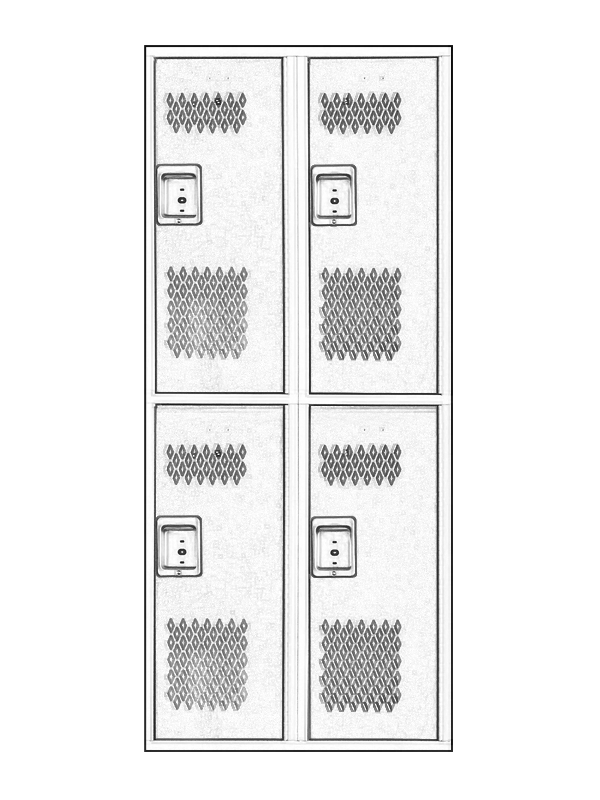

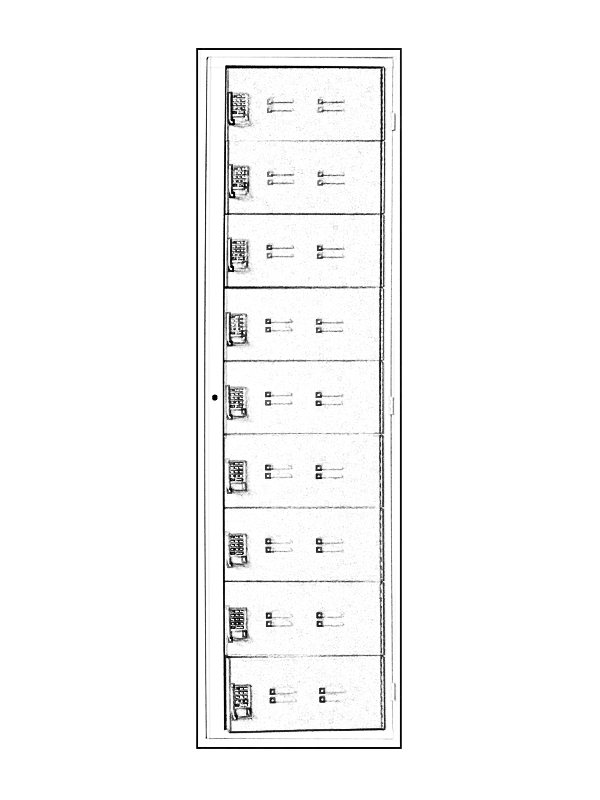

Size and configuration: Determine the size and configuration of the locker you need based on the number and types of items you will be storing. Consider the available space and how the lockers will fit into the overall layout of the area.

Security: Consider the level of security you require for your stored items. Look for lockers with secure locking mechanisms, such as padlocks or combination locks.

Material: Choose a material that will be durable and long-lasting, such as steel or aluminum. Look for lockers with thick gauge metal and strong construction.

Customization options: Look for lockers that can be customized to meet your specific needs, such as locker size, door options, color, and finish.

Ventilation: Consider whether you need lockers with ventilation or other features to prevent mold, mildew, or odor buildup.

Budget: Determine your budget and look for lockers that fit within your price range.

Manufacturer reputation: Choose a reputable manufacturer with a track record of producing high-quality, durable lockers.

By considering these factors, you can choose the welded locker that best meets your needs in terms of size, security, durability, customization, and budget.

English

English 中文简体

中文简体